A plastic material is any of a wide range of synthetic or semi-synthetic organicsolids that are moldable. Plastics are typically organic polymers of highmolecular mass, but they often contain other substances. They are usually synthetic, most commonly derived from petrochemicals, but many are partially natural.[1]

[edit]

Almost invariably, organic polymers mainly comprise plastics. The vast majority of these polymers are based on chains of carbon atoms alone or withoxygen, sulfur, or nitrogen as well. The backbone is that part of the chain on the main "path" linking a large number of repeat units together. To customize the properties of a plastic, different molecular groups "hang" from the backbone (usually they are "hung" as part of the monomers before linking monomers together to form the polymer chain). The structure of these "side chains" influence the properties of the polymer. This fine tuning of the properties of the polymer by repeating unit's molecular structure has allowed plastics to become an indispensable part of the twenty-first century world.Composition

[edit]Additives

Most plastics contain other organic or inorganic compounds blended in. The amount of additives ranges from zero percentage for polymers used to wrap foods to more than 50% for certain electronic applications. The average content of additives is 20% by weight of the polymer. Fillers improve performance and/or reduce production costs. Stabilizing additives include fire retardants to lower the flammability of the material. Many plastics contain fillers, relatively inert and inexpensive materials that make the product cheaper by weight. Typically fillers are mineral in origin, e.g., chalk. Some fillers are more chemically active and are called reinforcing agents. Since many organic polymers are too rigid for particular applications, they are blended with plasticizers, oily compounds that confer improvedrheology. Colourants are of course common additives, although their weight contribution is small. Many of the controversies associated with plastics are associated with the additives.[2]

[edit]Classification

Plastics are usually classified by their chemical structure of the polymer's backbone and side chains. Some important groups in these classifications are the acrylics, polyesters, silicones, polyurethanes, and halogenated plastics. Plastics can also be classified by the chemical process used in their synthesis, such as condensation, polyaddition, and cross-linking.[3]

[edit]Thermoplastics and thermosetting polymers

There are two types of plastics: thermoplastics and thermosetting polymers. Thermoplastics are the plastics that do not undergo chemical change in their composition when heated and can be moulded again and again. Examples include polyethylene,polypropylene, polystyrene, polyvinyl chloride, and polytetrafluoroethylene (PTFE).[4] Common thermoplastics range from 20,000 to 500,000 amu, while thermosets are assumed to have infinite molecular weight. These chains are made up of many repeating molecular units, known as repeat units, derived from monomers; each polymer chain will have several thousand repeating units.

Thermosets can melt and take shape once; after they have solidified, they stay solid. In the thermosetting process, a chemical reaction occurs that is irreversible. The vulcanization of rubber is a thermosetting process. Before heating with sulfur, the polyisoprene is a tacky, slightly runny material, but after vulcanization the product is rigid and non-tacky.

[edit]Other classifications

Other classifications are based on qualities that are relevant for manufacturing or product design. Examples of such classes are the thermoplastic and thermoset, elastomer, structural, biodegradable, and electrically conductive. Plastics can also be classified by various physical properties, such as density, tensile strength, glass transition temperature, and resistance to various chemical products.

[edit]Biodegradability

Main article: Biodegradable plastic

Biodegradable plastics break down (degrade) upon exposure to sunlight (e.g., ultra-violet radiation), water or dampness, bacteria, enzymes, wind abrasion, and in some instances rodent pest or insect attack are also included as forms of biodegradation orenvironmental degradation. Some modes of degradation require that the plastic be exposed at the surface, whereas other modes will only be effective if certain conditions exist in landfill or composting systems. Starch powder has been mixed with plastic as a filler to allow it to degrade more easily, but it still does not lead to complete breakdown of the plastic. Some researchers have actuallygenetically engineered bacteria that synthesize a completely biodegradable plastic, but this material, such as Biopol, is expensive at present.[5] The German chemical company BASF makes Ecoflex, a fully biodegradable polyester for food packaging applications.

[edit]Natural vs synthetic

Main article: Bioplastic

Most plastics are produced from petrochemicals. Motivated by the finiteness of petrochemical reserves and possibility of global warming, bioplastics are being developed. Bioplastics are made substantially from renewable plant materials such as cellulose and starch.[6]

In comparison to the global consumption of all flexible packaging, estimated at 12.3 million tonnes, estimates put global production capacity at 327,000 tonnes for related bio-derived materials.[7][8]

[edit]Crystalline vs amorphous

Some plastics are partially crystalline and partially amorphous in molecular structure, giving them both a melting point (the temperature at which the attractive intermolecular forces are overcome) and one or more glass transitions (temperatures above which the extent of localized molecular flexibility is substantially increased). The so-called semi-crystalline plastics include polyethylene, polypropylene, poly (vinyl chloride), polyamides (nylons), polyesters and some polyurethanes. Many plastics are completely amorphous, such as polystyrene and its copolymers, poly (methyl methacrylate), and all thermosets.

[edit]History

Early plastics were bio-derived materials such as egg and blood proteins, which are organic polymers. Treated cattle horns were used as windows for lanterns in the Middle Ages. Materials that mimicked the properties of horns were developed by treating milk-proteins (casein) with lye. In the 1800s the development of plastics accelerated with Charles Goodyear's discovery of vulcanization as a route to thermoset materials derived from natural rubber. Many storied materials were reported as industrial chemistry was developed in the 1800s. In the early 1900s, Bakelite, the first fully synthetic thermoset was reported by Belgian chemist Leo Baekeland. After the First World War, improvements in chemical technology led to an explosion in new forms of plastics. Among the earliest examples in the wave of new polymers were polystyrene (PS) and polyvinyl chloride (PVC). The development of plastics has come from the use of natural plastic materials (e.g., chewing gum, shellac) to the use of chemically modified natural materials (e.g., rubber, nitrocellulose, collagen, galalite) and finally to completely synthetic molecules (e.g., bakelite, epoxy, polyvinyl chloride).

[edit]Parkesine

The plastic material, parkesine, was patented by Alexander Parkes, In Birmingham, UK in 1856.[9] It was unveiled at the 1862 Great International Exhibition in London.[10] Parkesine won a bronze medal at the 1862 World's fair in London. Parkesine was made from cellulose (the major component of plant cell walls) treated with nitric acid as a solvent. The output of the process (commonly known as cellulose nitrate or pyroxilin) could be dissolved in alcohol and hardened into a transparent and elastic material that could be molded when heated.[11] By incorporating pigments into the product, it could be made to resemble ivory.

[edit]Bakelite

Main article: Bakelite

The first so called plastic based on a synthetic polymer was made from phenol and formaldehyde, with the first viable and cheap synthesis methods invented in 1907, by Leo Hendrik Baekeland, a Belgian-born American living in New York state. Baekeland was looking for an insulating shellac to coat wires in electric motors and generators. He found that combining phenol (C6H5OH) and formaldehyde (HCOH) formed a sticky mass and later found that the material could be mixed with wood flour, asbestos, or slate dust to create strong and fire resistant "composite" materials. The new material tended to foam during synthesis, requiring that Baekeland build pressure vessels to force out the bubbles and provide a smooth, uniform product, as he announced in 1909, in a meeting of the American Chemical Society.[12] Bakelite was originally used for electrical and mechanical parts, coming into widespread use in consumer goods in the 1920s. Bakelite was a purely synthetic material, not derived from living matter. It was also an early thermosetting plastic.

[edit]Representative polymers

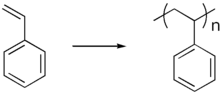

[edit]Polystyrene

Main articles: Polystyrene and PVC

Polystyrene is a rigid, brittle, inexpensive plastic that has been used to make plastic modelkits and similar knick-knacks. It would also be the basis for one of the most popular "foamed" plastics, under the name styrene foam or Styrofoam. Foam plastics can be synthesized in an "open cell" form, in which the foam bubbles are interconnected, as in an absorbent sponge, and "closed cell", in which all the bubbles are distinct, like tiny balloons, as in gas-filled foam insulation and flotation devices. In the late 1950s, high impact styrene was introduced, which was not brittle. It finds much current use as the substance of toy figurines and novelties.

[edit]Polyvinyl chloride

Polyvinyl chloride (PVC, commonly called "vinyl")[13] incorporates chlorine atoms. The C-Cl bonds in the backbone are hydrophobic and resist oxidation (and burning). PVC is stiff, strong, heat and weather resistant, properties that recommend its use in devices for plumbing, gutters, house siding, enclosures for computers and other electronics gear. PVC can also be softened with chemical processing, and in this form it is now used for shrink-wrap, food packaging, and rain gear.

All PVC polymers are degraded by heat and light. When this happens, hydrogen chloride is released into the atmosphere and oxidation of the compound occurs.[14] Because hydrogen chloride readily combines with water vapor in the air to form hydrochloric acid,[15] polyvinyl chloride is not recommended for long-term archival storage of silver, photographic film or paper (mylar is preferable).[16]

[edit]Nylon

Main article: Nylon

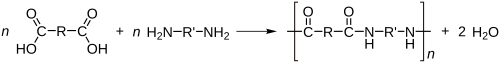

The plastics industry was revolutionized in the 1930s with the announcement of polyamide (PA), far better known by its trade namenylon. Nylon was the first purely synthetic fiber, introduced by DuPont Corporation at the 1939 World's Fair in New York City.

In 1927, DuPont had begun a secret development project designated Fiber66, under the direction of Harvard chemist Wallace Carothersand chemistry department director Elmer Keiser Bolton. Carothers had been hired to perform pure research, and he worked to understand the new materials' molecular structure and physical properties. He took some of the first steps in the molecular design of the materials.

His work led to the discovery of synthetic nylon fiber, which was very strong but also very flexible. The first application was for bristles for toothbrushes. However, Du Pont's real target was silk, particularly silk stockings. Carothers and his team synthesized a number of different polyamides including polyamide 6.6 and 4.6, as well as polyesters.[17]

It took DuPont twelve years and US$27 million to refine nylon, and to synthesize and develop the industrial processes for bulk manufacture. With such a major investment, it was no surprise that Du Pont spared little expense to promote nylon after its introduction, creating a public sensation, or "nylon mania".

Nylon mania came to an abrupt stop at the end of 1941 when the USA entered World War II. The production capacity that had been built up to produce nylon stockings, or just nylons, for American women was taken over to manufacture vast numbers of parachutes for fliers and paratroopers. After the war ended, DuPont went back to selling nylon to the public, engaging in another promotional campaign in 1946 that resulted in an even bigger craze, triggering the so called nylon riots.

Subsequently polyamides 6, 10, 11, and 12 have been developed based on monomers which are ring compounds; e.g. caprolactam. Nylon 66 is a material manufactured by condensation polymerization.

Nylons still remain important plastics, and not just for use in fabrics. In its bulk form it is very wear resistant, particularly if oil-impregnated, and so is used to build gears, plain bearings, and because of good heat-resistance, increasingly for under-the-hood applications in cars, and other mechanical parts.

[edit]Rubber

Natural rubber is an elastomer (an elastic hydrocarbon polymer) that was originally derived from latex, a milky colloidal suspensionfound in the sap of some plants. It is useful directly in this form (indeed, the first appearance of rubber in Europe was cloth waterproofed with unvulcanized latex from Brazil) but, later, in 1839, Charles Goodyear invented vulcanized rubber; this a form of natural rubber heated with, mostly, sulfur forming cross-links between polymer chains (vulcanization), improving elasticity and durability.

[edit]Synthetic rubber

Main article: Synthetic rubber

The first fully synthetic rubber was synthesized by Sergei Lebedev in 1910. In World War II, supply blockades of natural rubber fromSouth East Asia caused a boom in development of synthetic rubber, notably styrene-butadiene rubber. In 1941, annual production of synthetic rubber in the U.S. was only 231 tonnes which increased to 840,000 tonnes in 1945. In the space race and nuclear arms race,Caltech researchers experimented with using synthetic rubbers for solid fuel for rockets. Ultimately, all large military rockets and missiles would use synthetic rubber based solid fuels, and they would also play a significant part in the civilian space effort.

[edit]Properties of plastics

The properties of plastics is defined chiefly by the organic chemistry of the polymer. such as hardness, density, and resistance to heat, organic solvents, oxidation, and ionizing radiation. In particular, most plastics will melt upon heating to a few hundred degreescelsius.[18] While plastics can be made electrically conductive, with the conductivity of up to 80 kS/cm in stretch-orientedpolyacetylene,[19] they are still no match for most metals like copper which have conductivities of several hundreds kS/cm.

[edit]Toxicity

Due to their insolubility in water and relative chemical inertness, pure plastics generally have low toxicity. Some plastic products contain a variety of additives, some of which can be toxic. For example, plasticizers like adipates and phthalates are often added to brittle plastics like polyvinyl chloride to make them pliable enough for use in food packaging, toys, and many other items. Traces of these compounds can leach out of the product. Owing to concerns over the effects of such leachates, the European Union has restricted the use of DEHP (di-2-ethylhexyl phthalate)and other phthalates in some applications. Some compounds leaching from polystyrene food containers have been proposed to interfere with hormone functions and are suspected human carcinogens.[20]

Whereas the finished plastic may be non-toxic, the monomers used in the manufacture of the parent polymers may be toxic. In some cases, small amounts of those chemicals can remain trapped in the product unless suitable processing is employed. For example, theWorld Health Organization's International Agency for Research on Cancer (IARC) has recognized that vinyl chloride, the precursor to PVC, as a human carcinogen.[20]

[edit]BPA controversy

Some polymers may also decompose into the monomers or other toxic substances when heated. In 2011, it was reported that "almost all plastic products" sampled released chemicals with estrogenic activity, although the researchers identified plastics which did not leach chemicals with estrogenic activity.[21]

The primary building block of polycarbonates, bisphenol A (BPA), is an estrogen-like endocrine disruptor that may leach into food.[20]Research in Environmental Health Perspectives finds that BPA leached from the lining of tin cans, dental sealants and polycarbonate bottles can increase body weight of lab animals' offspring.[22] A more recent animal study suggests that even low-level exposure to BPA results in insulin resistance, which can lead to inflammation and heart disease.[23]

As of January 2010, the LA Times newspaper reports that the United States FDA is spending $30 million to investigate indications of BPA being linked to cancer.[24]

Bis(2-ethylhexyl) adipate, present in plastic wrap based on PVC, is also of concern, as are the volatile organic compounds present innew car smell.

The European Union has a permanent ban on the use of phthalates in toys. In 2009, the United States government banned certain types of phthalates commonly used in plastic.[25]

[edit]Environmental issues

Further information: Marine debris and Great Pacific Garbage Patch

Plastics are durable and degrade very slowly; the chemical bonds that make plastic so durable make it equally resistant to natural processes of degradation. Since the 1950s, one billion tons of plastic have been discarded and may persist for hundreds or even thousands of years.[26] Perhaps the biggest environmental threat from plastic comes from nurdles,[27] which are the raw material from which all plastics are made. They are tiny pre-plastic pellets that kill large numbers of fish and birds that mistake them for food.

Prior to the ban on the use of CFCs in extrusion of polystyrene (and general use, except in life-critical fire suppression systems; seeMontreal Protocol), the production of polystyrene contributed to the depletion of the ozone layer; however, non-CFCs are currently used in the extrusion process.

[edit]Incineration of plastics

Plastic can be converted as a fuel since they are usually hydrocarbon-based and can be broken down into liquid hydrocarbon. One kilogram of waste plastic produces a liter of hydrocarbon.[28] In some cases, burning plastic can release toxic fumes. Burning the plastic polyvinyl chloride (PVC) may create dioxin.[29]

[edit]Recycling

Thermoplastics can be remelted and reused, and thermoset plastics can be ground up and used as filler, although the purity of the material tends to degrade with each reuse cycle. There are methods by which plastics can be broken back down to a feedstock state.

The greatest challenge to the recycling of plastics is the difficulty of automating the sorting of plastic wastes, making it labor intensive. Typically, workers sort the plastic by looking at the resin identification code, although common containers like soda bottles can be sorted from memory. Typically, the caps for PETE bottles are made from a different kind of plastic which is not recyclable, which presents additional problems to the automated sorting process. Other recyclable materials such as metals are easier to process mechanically. However, new processes of mechanical sorting are being developed to increase capacity and efficiency of plastic recycling.

While containers are usually made from a single type and color of plastic, making them relatively easy to be sorted, a consumer product like a cellular phone may have many small parts consisting of over a dozen different types and colors of plastics. In such cases, the resources it would take to separate the plastics far exceed their value and the item is discarded. However, developments are taking place in the field of active disassembly, which may result in more consumer product components being re-used or recycled. Recycling certain types of plastics can be unprofitable, as well. For example, polystyrene is rarely recycled because it is usually not cost effective. These unrecycled wastes are typically disposed of in landfills, incinerated or used to produce electricity at waste-to-energy plants.

A first success in recycling of plastics is Vinyloop, a recycling process and an approach of the industry to separate PVC from other materials through a process of dissolution, filtration and separation of contaminations. A solvent is used in a closed loop to elute PVC from the waste. This makes it possible to recycle composite structure PVC waste which normally is being incinerated or put in a landfill. Vinyloop-based recycled PVC's primary energy demand is 46 percent lower than conventional produced PVC. The global warming potential is 39 percent lower. This is why the use of recycled material leads to a significant better ecological footprint.[30]

In 1988, to assist recycling of disposable items, the Plastic Bottle Institute of the Society of the Plastics Industry devised a now-familiar scheme to mark plastic bottles by plastic type. A plastic container using this scheme is marked with a triangle of three "chasing arrows", which encloses a number giving the plastic type:

Plastics type marks: the resin identification code[31]

- PET (PETE), polyethylene terephthalate

- HDPE, high-density polyethylene

- PVC, polyvinyl chloride

- LDPE, low-density polyethylene,

- PP, polypropylene

- PS, polystyrene

- Other types of plastics (see list, below)

[edit]Common plastics and uses

Due to their relatively low cost, ease of manufacture, versatility, and imperviousness to water, plastics are used in an enormous and expanding range of products, from paper clips to spaceships. They have already displaced many traditional materials, such as wood,stone, horn and bone, leather, paper, metal, glass, and ceramic, in most of their former uses.

- Polyester (PES) – Fibers, textiles.

- Polyethylene terephthalate (PET) – Carbonated drinks bottles, peanut butter jars, plastic film, microwavable packaging.

- Polyethylene (PE) – Wide range of inexpensive uses including supermarket bags, plastic bottles.

- High-density polyethylene (HDPE) – Detergent bottles, milk jugs, and molded plastic cases.[32]

- Polyvinyl chloride (PVC) – Plumbing pipes and guttering, shower curtains, window frames, flooring.

- Polyvinylidene chloride (PVDC) (Saran) – Food packaging.

- Low-density polyethylene (LDPE) – Outdoor furniture, siding, floor tiles, shower curtains, clamshell packaging.

- Polypropylene (PP) – Bottle caps, drinking straws, yogurt containers, appliances, car fenders (bumpers), plastic pressure pipe systems.

- Polystyrene (PS) – Packaging foam/"peanuts", food containers, plastic tableware, disposable cups, plates, cutlery, CD and cassette boxes.

- High impact polystyrene (HIPS) -: Refrigerator liners, food packaging, vending cups.

- Polyamides (PA) (Nylons) – Fibers, toothbrush bristles, fishing line, under-the-hood car engine moldings.

- Acrylonitrile butadiene styrene (ABS) – Electronic equipment cases (e.g., computer monitors, printers, keyboards), drainage pipe.

- Polycarbonate (PC) – Compact discs, eyeglasses, riot shields, security windows, traffic lights, lenses.

- Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) – A blend of PC and ABS that creates a stronger plastic. Used in car interior and exterior parts, and mobile phone bodies.

- Polyurethanes (PU) – Cushioning foams, thermal insulation foams, surface coatings, printing rollers (Currently 6th or 7th most commonly used plastic material, for instance the most commonly used plastic found in cars).

[edit]Special purpose plastics

- Melamine formaldehyde (MF) – One of the aminoplasts, and used as a multi-colorable alternative to phenolics, for instance in moldings (e.g., break-resistance alternatives to ceramic cups, plates and bowls for children) and the decorated top surface layer of the paper laminates (e.g., Formica).

- Plastarch material – Biodegradable and heat resistant, thermoplastic composed of modified corn starch.

- Phenolics (PF) or (phenol formaldehydes) – High modulus, relatively heat resistant, and excellent fire resistant polymer. Used for insulating parts in electrical fixtures, paper laminated products (e.g., Formica), thermally insulation foams. It is a thermosetting plastic, with the familiar trade name Bakelite, that can be molded by heat and pressure when mixed with a filler-like wood flour or can be cast in its unfilled liquid form or cast as foam (e.g., Oasis). Problems include the probability of moldings naturally being dark colors (red, green, brown), and as thermoset it is difficult to recycle.

- Polyetheretherketone (PEEK) – Strong, chemical- and heat-resistant thermoplastic, biocompatibility allows for use in medical implant applications, aerospace moldings. One of the most expensive commercial polymers.

- Polyetherimide (PEI) (Ultem) – A high temperature, chemically stable polymer that does not crystallize.

- Polylactic acid (PLA) – A biodegradable, thermoplastic found converted into a variety of aliphatic polyesters derived from lactic acidwhich in turn can be made by fermentation of various agricultural products such as corn starch, once made from dairy products.

- Polymethyl methacrylate (PMMA) – Contact lenses, glazing (best known in this form by its various trade names around the world; e.g., Perspex, Oroglas, Plexiglas), aglets, fluorescent light diffusers, rear light covers for vehicles. It forms the basis of artistic and commercial acrylic paints when suspended in water with the use of other agents.

- Polytetrafluoroethylene (PTFE) – Heat-resistant, low-friction coatings, used in things like non-stick surfaces for frying pans, plumber's tape and water slides. It is more commonly known as Teflon.

- Urea-formaldehyde (UF) – One of the aminoplasts and used as a multi-colorable alternative to phenolics. Used as a wood adhesive (for plywood, chipboard, hardboard) and electrical switch housings.

[edit]Material properties of some thermoplastics

| name | Symbol | Density [g/cm3] | Tensile strength [MPa] | Flexural strength [MPa] | Elastic modulus [GPa] | Elongation at rupture [%] | Thermal stability [°C] | Expansion at 20°C [10−6/°C] | |

|---|---|---|---|---|---|---|---|---|---|

| High DensityPolyethylene | HDPE | 0.95 | 31 | 40 | 1.86 | 100 | 120 | 126 | [33] |

| Low DensityPolyethylene | LDPE | 0.92 | 17 | 14 | 0.29 | 500 | 90 | 160 | |

| Polyvinyl Chloride | PVC | 1.44 | 47 | 91 | 3.32 | 60 | 80 | 75 | |

| Polypropylene | PP | 0.91 | 37 | 49 | 1.36 | 350 | 150 | 90 | |

| Polyethylene terephthalate | PET | 1.35 | 61 | 105 | 1.35 | 170 | 120 | 70 | |

| Polymethylmethacrylate | PMMA | 1.19 | 61 | 103 | 2.77 | 4 | 100 | 65 | |

| Polycarbonate | PC | 1.2 | 68 | 95 | 2.3 | 130 | 120 | 66 | |

| Acrylonitrile butadiene styrene | ABS | 1.05 | 45 | 70 | 2.45 | 33 | 70 | 90 | |

| Polyamide | Nylon 6 | 1.13 | 60 | 91 | 2.95 | 60 | 110 | 66 | |

| Polyimide | PI | 1.38 | 96 | 143 | 3.1 | 7 | 380 | 43 | |

| Polysulfone | PSF | 1.25 | 68 | 115 | 2.61 | 75 | 160 | 56 | |

| Polyamide-imide, electrical grade | PAI | 1.41 | 138 | 193 | 4.1 | 12 | 260 | 30 | |

| Polyamide-imide, bearing grade | PAI | 1.46 | 103 | 159 | 5.5 | 6 | 260 | 25 | |

| Polytetrafluoroethylene | PTFE | 2.17 | 24 | 33 | 0.49 | 300 | 260 | 95 | |

| Polyetherimide | PEI | 1.27 | 105 | 151 | 2.9 | 60 | 210 | 31 | [34] |

| Polyether ether ketone | PEEK | 1.32 | 100 | 3.6 | 50 | 343 | |||

| Polyaryletherketone(strong) | PEAK | 1.46 | 136 | 213 | 12.4 | 2.1 | 267 | ||

| Polyaryletherketone(tough) | PEAK | 1.29 | 87 | 124 | 3 | 40 | 190 | ||

| Self-reinforcedpolyphenylene | SRP | 1.19 | 152 | 234 | 5.52 | 10 | 151 | ||

| Polyamide-imide | PAI | 1.42 | 152 | 241 | 4.9 | 15 | 278 |

NOTE: Bulk properties of pure cast or hot formed materials. Properties could change considerably by mechanical treatment and cold forming. Fiber and foils are not considered.

[edit]Etymology

The word plastic is derived from the Greek πλαστικός (plastikos) meaning capable of being shaped or molded, from πλαστός (plastos) meaning molded.[35][36] It refers to their malleability, or plasticity during manufacture, that allows them to be cast, pressed, or extrudedinto a variety of shapes—such as films, fibers, plates, tubes, bottles, boxes, and much more.

The common word plastic should not be confused with the technical adjective plastic, which is applied to any material which undergoes a permanent change of shape (plastic deformation) when strained beyond a certain point. Aluminum which is stamped or forged, for instance, exhibits plasticity in this sense, but is not plastic in the common sense; in contrast, in their finished forms, some plastics will break before deforming and therefore are not plastic in the technical sense.

No comments:

Post a Comment

Jayant Parkash Is Welcome All world to my blog